- Higher volume of paste release

- More uniform shape on solder deposits

- Higher transfer efficiency and print yields

- Greater yields on low-area-ratio/miniaturized applications

- Higher screen printer thru-put and lower residual material costs due to reduced underside wiping

- Reduced surface energy of the paste contact area

- Better contour definition and lower failure

- Solder paste bridging is minimized as well, which leads to higher process stability and lower failure rates

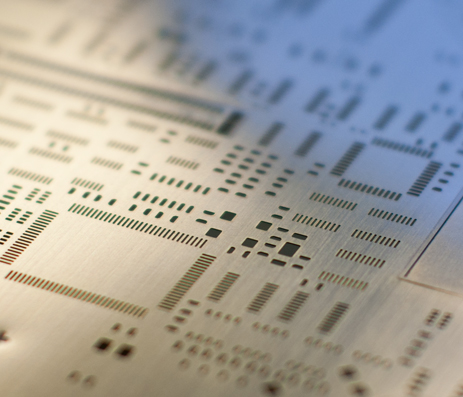

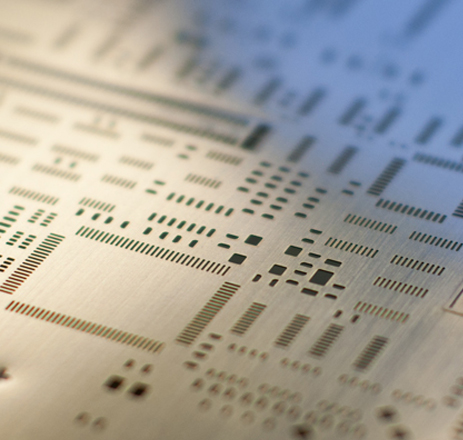

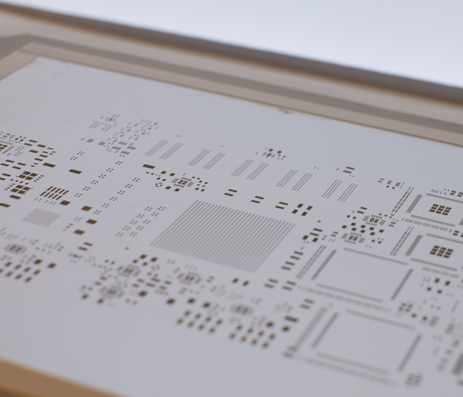

Anti-Adhesion Advanced Nano Coated Stencils

StenTech’s Advanced Nano stencil has a highly unique and patented coating that is applied to the bottom side of the stencil AND inside the apertures; however, the squeegee remains uncoated. This advanced coating provides the stencil with anti-adhesion properties.

StenTech’s Advanced Nano stencil utilizes a specialized 1-2 µm hardened nano coating inside every aperture and on the bottom side of the stencil. This permanent hydrophobic coating repels solder paste.

Optimized aspect and area ratio significantly reduces the adhesion of the solder paste on the bottom side of the stencil and inside the apertures. Therefore, the contour definition of the solder paste deposit is improved and constant transferred solder paste volumes are realized.

The unique “easy-to-clean” surface of the Advanced Nano Coating stencil significantly reduces the adhesion of the solder paste on the bottom side of the stencil and inside the apertures. Solder paste bridging is minimized, which leads to higher process stability and lower failure rates.

Get a quote