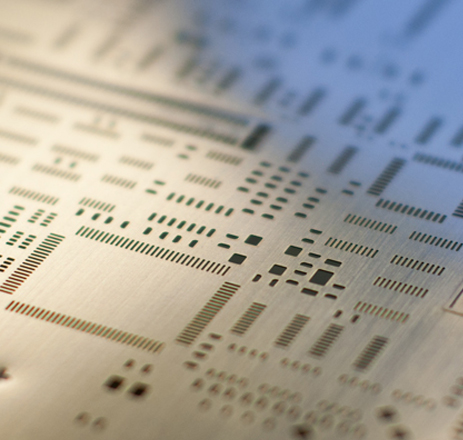

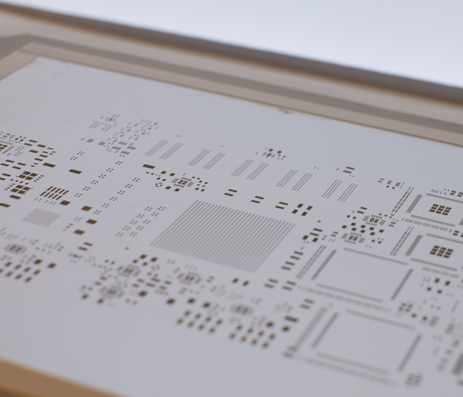

SMT Emulsion Screen Printing

Emulsion screens are one of the oldest forms of printing, and remain the most versatile to this day. Emulsion screens begin with a frame. The mesh is stretched onto this frame, and then the emulsion is applied. The mesh is then imaged, ready for printing. Emulsion screens are used in many forms and industries, such as automotive and microelectronics; these industries require precise and accurate deposits and line widths. StenTech's screens are manufactured to maintain these specifications. The main application area of emulsion screens are display and advertising, aerospace, microelectronics, textile printing, ceramic printing, circuit boards and glasses. StenTech offers a full range of mesh for every application.

There are different weaves and thread thicknesses of mesh. Fabrics are available in polyester, stainless steel, nickel mesh and a nickel-polyester combination.

Get a quote