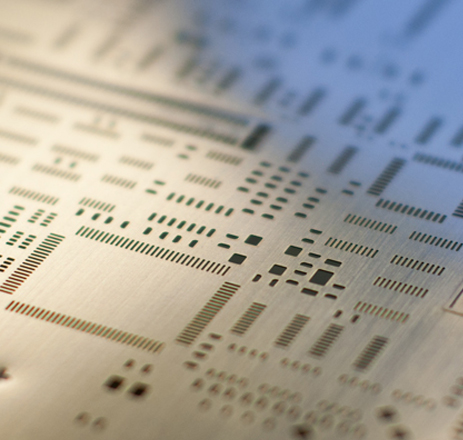

- Precise and controlled process

- Custom thickness can be achieved

- Very smooth trapezoidal walls

- Better release of paste compared to laser-cut or chem-etched

- Provides fine and ultrafine pitch apertures with paste transfer efficiencies at 95% and above

- Provides longer stencil life (electroform stencils are generally 1.5 times harder than stainless steel of comparable thickness)

- Nickel electroform offers lower coefficient of friction compared to steel, which allows better roll of paste and decreases squeegee wear

- Stencils with large aperture counts/dense images can be done without metal distortion (no heat transfer)

- Absolutely no burr (no need of buffing or polishing)

- Thickness of stencil range from 0.001" to 0.008" in 0.0001" increments and with multi-steps

- Positional accuracy 0.002" over 16" image area

| Thickness(mil) | Max foil size | Thickness Tolerance | Min aperture size | Min gap b/w openings |

|---|---|---|---|---|

| 0.5 to 1.0 | 12" x 12" | +/-0.0001" | 0.002" | 0.003" |

| 1.0 to 2.0 | 18" x 18" | +/-0.0002" | 0.003" | 0.004" |

| 2.0 to 3.0 | 21.5" x21.5 | +/-0.0003" | 0.004" | 0.004" |

| 3.0 to 4.0 | 21.5" x24 | +/-0.0004" | 0.0045" | 0.005" |

| 4.0 to 5.0 | 21.5" x 24" | +/-0.0004" | 0.005" | 0.006" |

| 5.0 to 6.0 | 21.5" x 24" | +/-0.0005" | 0.006" | 0.006" |

| 6.0 to 7.0 | 21.5" x 24" | +/-0.0005" | 0.0075" | 0.0075" |

| 7.0 to 8.0 | 21.5" x 24" | +/-0.0005" | 0.0075" | 0.0075" |

Note: Thickness tolerance is based on the design (image). These are the max tolerance limits with in the image area.